Introduction to Oxy Gas Welding Kits

Oxy gas welding is a versatile and widely used technique for joining metals, enabling both cutting and welding tasks in various applications. At the heart of this process is the oxy gas welding kit, which combines two gases—oxygen and acetylene—to produce a high-temperature flame. This flame is utilized to heat metal to its melting point, allowing it to fuse with other pieces. In this comprehensive guide, we’ll explore what oxy gas welding kits are, their key components, applications, and how to choose the best kit for your needs.

What is an Oxy Gas Welding Kit?

An oxy gas welding kit is a collection of equipment designed for welding and cutting metal using an oxy-fuel process. This method involves the controlled combustion of a mixture of oxygen and a fuel gas, typically acetylene, to generate a flame capable of melting metals. The kits vary in terms of size, components, and capabilities, catering to different welding and cutting needs, from small DIY tasks to large industrial operations.

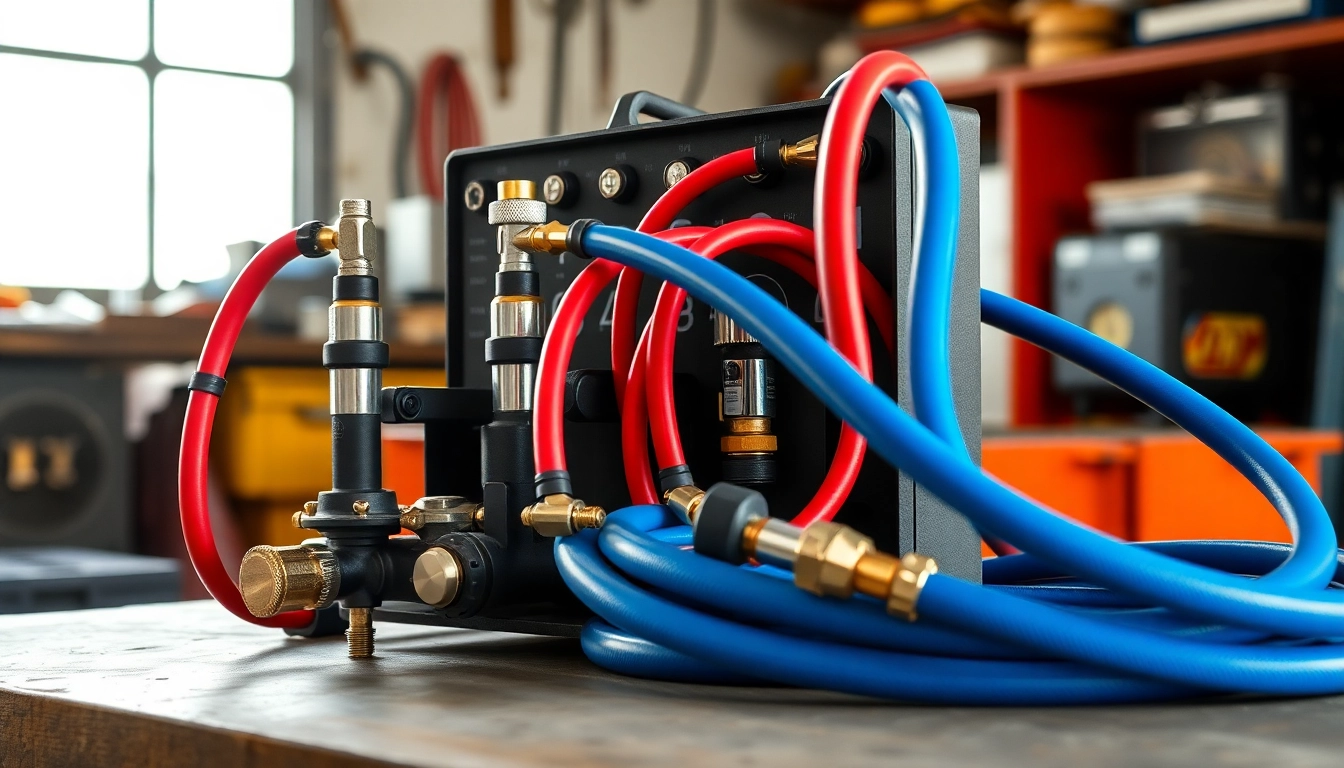

Key Components of Oxy Gas Welding Kits

The components of an oxy gas welding kit typically include:

- Oxygen Cylinder: A high-pressure cylinder that stores oxygen. It is critical for producing a clean, intense flame.

- Acetylene Cylinder: A cylinder containing acetylene gas, which is mixed with oxygen to create the flame used for welding.

- Regulators: These devices control the flow of gases from the cylinders, ensuring the right mixture reaches the torch.

- Welding Torch: The tool that mixes the oxygen and acetylene to produce the flame. It has interchangeable nozzles for different flame sizes.

- Hoses: Flexible tubes that transport the gases from the cylinders to the torch. They are usually color-coded—green for oxygen and red for acetylene.

- Cutting Attachment: An optional component that allows users to cut through metal using the oxy-fuel flame.

- Safety Gear: Essential items like goggles, gloves, and jackets to protect the operator from heat and sparks.

Common Applications for Oxy Gas Welding

Oxy gas welding kits are utilized across various sectors due to their versatility. Some common applications include:

- Automotive Repair: Used for welding body panels, frames, and exhaust systems.

- Metal Fabrication: Essential for creating structures, frames, and custom parts across industries.

- Artistic Welding: Employed in creating sculptures and art pieces from metal.

- Plumbing: Utilized for joining pipes that require welding for durability.

Types of Oxy Gas Welding Kits

Standard Oxy Gas Welding Kits

Standard oxy gas welding kits are generally suited for everyday welding tasks. They contain all the basic components needed for most projects, making them a good choice for hobbyists and those engaged in light to moderate welding jobs. These kits typically include a robust welding torch, oxygen and acetylene tanks, and essential regulators and hoses.

Heavy-Duty Oxy Gas Welding Kits

Heavy-duty oxy gas welding kits are designed for industrial applications and can handle more rigorous tasks and materials. They often feature larger tanks, more powerful torches, and additional tools. These kits are ideal for professional welders who work with thicker materials or require higher temperatures.

Portable Oxy Gas Welding Kits

For those who need mobility, portable oxy gas welding kits come in handy. These kits are lighter and more compact, making them easy to transport from one job site to another. They often include smaller gas cylinders and more streamlined equipment, perfect for on-site repairs or maintenance work.

Factors to Consider When Buying an Oxy Gas Welding Kit

Budget and Price Range

When purchasing an oxy gas welding kit, your budget will often be a primary consideration. Prices can vary significantly, with basic kits starting at around $100 and more advanced models exceeding $500. It’s essential to evaluate the features you need while remaining within your financial limits.

Brand Reputation and Reviews

Brand reputation plays a crucial role in ensuring you purchase a reliable oxy gas welding kit. Brands like Victor, Harris, and Lincoln Electric are well-known for their quality products. Checking customer reviews and feedback can provide valuable insights into the performance and durability of specific kits.

Included Accessories and Tools

When selecting a kit, examine what’s included. Basic kits may only contain the essential torch and hoses, while others might feature additional nozzles, a cutting attachment, or personal protective equipment. Consider what will serve your purposes best based on the types of projects you plan to undertake.

Safety Practices for Oxy Gas Welding

Essential Safety Gear

Safety should always be a priority in oxy gas welding. Essential safety gear includes:

- Welding Goggles: Protect your eyes from bright flames and harmful rays.

- Flame-Resistant Gloves: Shield your hands from heat and sparks.

- Protective Clothing: Wear long-sleeve shirts and pants made of flame-resistant materials.

- Face Shields: For added protection against sparks and heat.

Best Practices to Avoid Accidents

To minimize risks while welding, adhere to the following best practices:

- Ensure proper ventilation in your workspace to prevent gas inhalation.

- Regularly inspect hoses for leaks or cracks before use.

- Never leave a welding torch unattended when lit, and always turn off the gas supply when finished.

- Keep a fire extinguisher nearby, as welding can produce sparks that ignite nearby materials.

Proper Storage of Oxy Gas Equipment

Correct storage of your oxy gas welding kit is vital for safety. Store cylinders upright, in a cool, dry area, away from heat sources and flammable materials. Secure cylinders to prevent them from falling over. Additionally, ensure that hoses and regulators are stored in a manner that prevents damage.

Tips for Maintaining Your Oxy Gas Welding Kit

Regular Cleaning and Inspection

Routine maintenance is crucial in prolonging the life of your oxy gas welding kit. Clean the torch and inspect all components regularly to identify wear or damage. Keeping the equipment lint and dust-free will help maintain performance and reduce the chances of malfunctions.

Repairing Common Issues

Welding equipment may encounter a variety of common issues, such as:

- Faulty Regulators: If gas flow is inconsistent, inspect for blockages and ensure connections are tight. Replace faulty regulators if needed.

- Leaking Hoses: Address leaks immediately, as they can pose fire hazards. Use soap solution to test for leaks and replace damaged hoses promptly.

- Clogged Nozzles: Clean nozzles regularly to ensure an even gas flow and flame efficiency.

When to Replace Components

Understanding when to replace parts of your oxy gas welding kit is essential:

- Hoses: Inspect hoses frequently for cracks or signs of wear. Replace them if you notice any damage.

- Regulators: If you find it difficult to maintain pressure or the gas supply starts fluctuating, it might be time for a replacement.

- Cylinders: Always check expiration dates and service marks on gas cylinders. When they reach their service limit, they must be replaced.

Conclusion

Oxy gas welding kits are invaluable tools in both professional and personal settings, enabling effective metal joining through a versatile process. By understanding the components, types, and safety practices associated with these kits, you can ensure a successful and safe welding experience. Whether you’re a novice welder or a seasoned professional, investing time in learning about oxy gas welding can pay off in the quality of your work and the safety of your environment.