Understanding the Oxy Gas Welding Kit

What is an Oxy Gas Welding Kit?

An oxy gas welding kit is a specialized tool set designed for welding and cutting metals via a flame produced by burning a mixture of oxygen and acetylene gas. This method of metal joining is known as oxy-fuel welding or oxy-acetylene welding. The kit typically includes the necessary hardware and accessories to safely conduct fabrication, repairs, and cutting tasks across various metals, making it a versatile solution for both hobbyists and professionals alike.

Components of a Complete Kit

A complete oxy gas welding kit generally consists of several essential components:

- Oxygen Cylinder: A portable cylinder containing compressed oxygen, crucial for combustion.

- Acetylene Cylinder: This cylindrical tank stores acetylene gas, which produces a high-temperature flame.

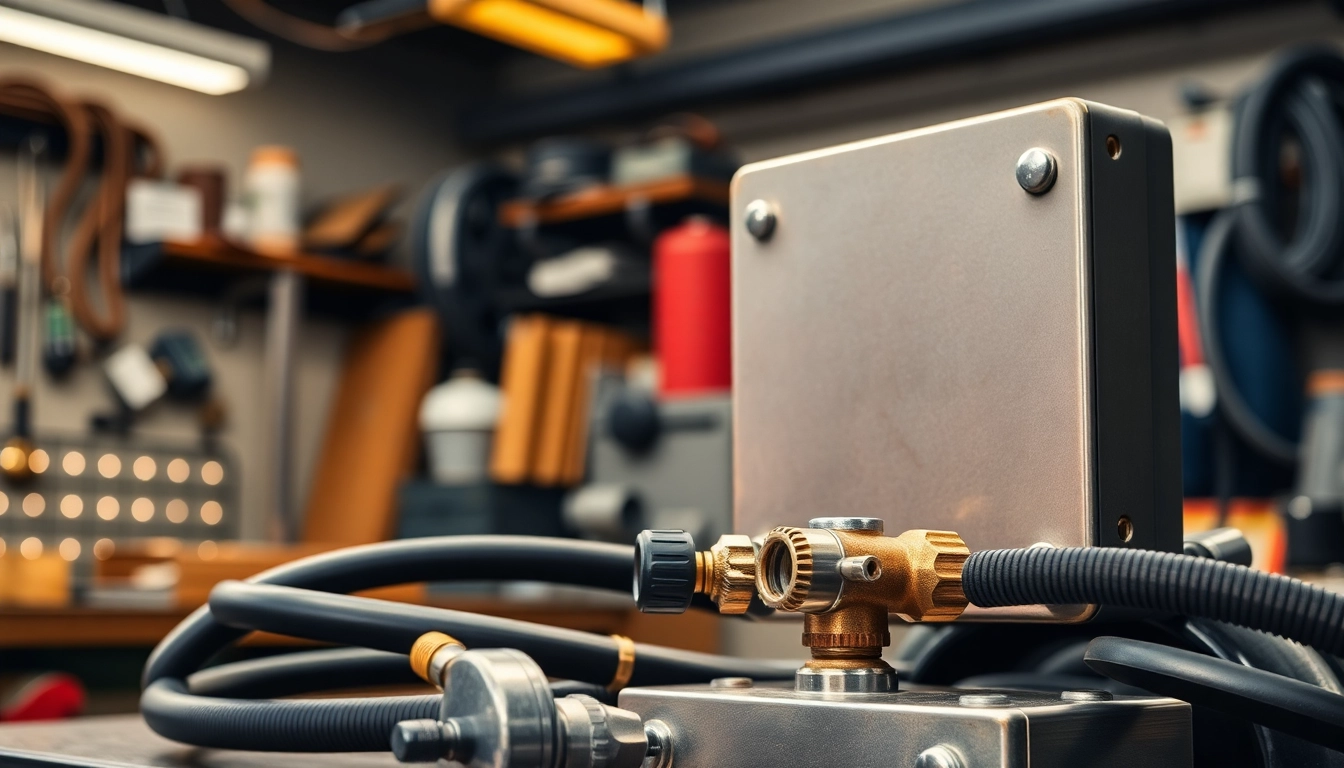

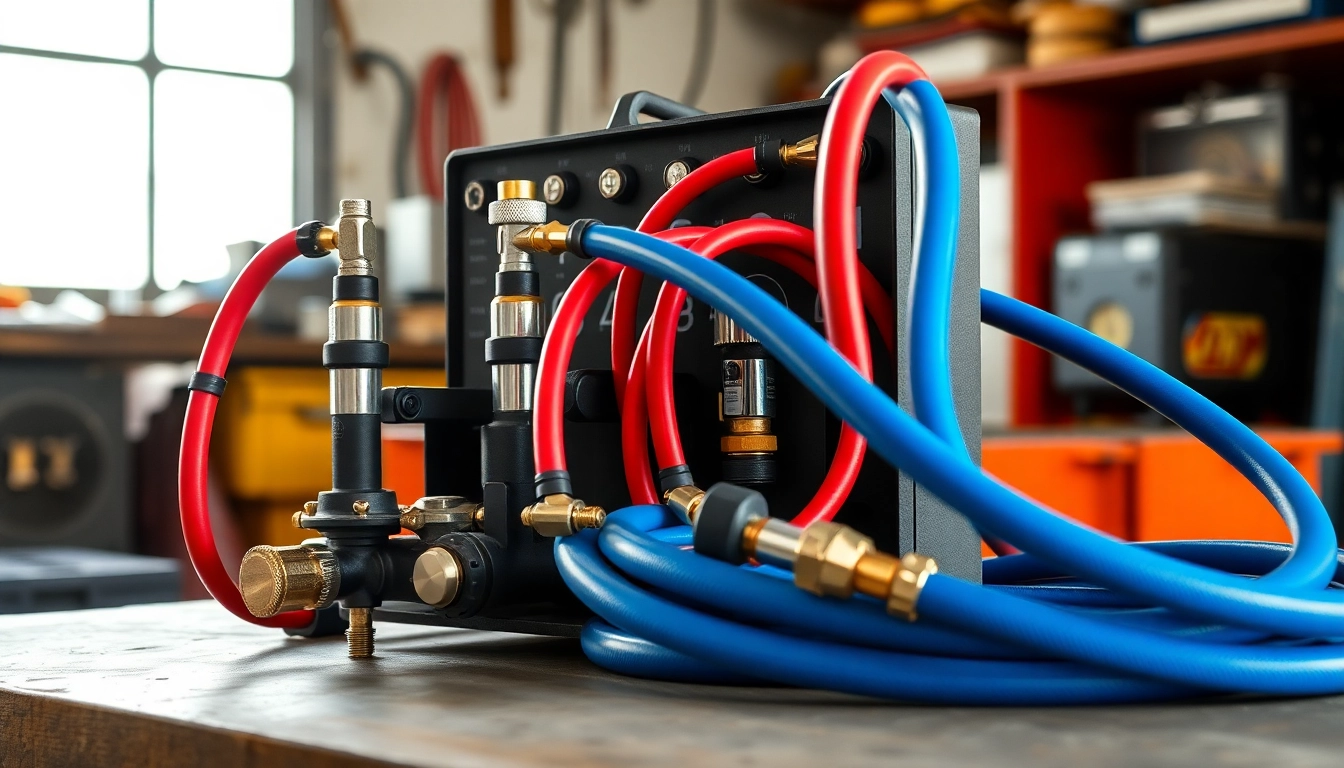

- Regulators: Devices attached to the cylinders that control gas flow and pressure, allowing for precise flame adjustments.

- Hoses: Flexible tubing that connects the regulators to the welding torch, responsible for conveying gases safely.

- Welding Torch: The tool where the gases mix and ignite, creating a flame used for welding or cutting.

- Welding Tips: Interchangeable tips of varying sizes designed for different welding tasks—from fine work to large-scale cuts.

- Safety Gear: Includes goggles, gloves, and flame-resistant clothing to ensure user safety during operation.

Key Benefits of Using an Oxy Gas Welding Kit

Utilizing an oxy gas welding kit offers numerous benefits:

- Versatility: Capable of welding, cutting, and heating various metals including steel, aluminum, and bronze.

- Portability: Many kits are designed to be compact and lightweight, making them easy to transport for on-site projects.

- Fast Setup: Oxy-acetylene welding systems can be set up relatively fast compared to electric welders, making them functional in quick job settings.

- Cost-Effective: Generally lower initial investment compared to some electric welding machines, along with relatively inexpensive gases.

- Superior Weld Quality: Produces high-quality welds and cuts that can be as strong as the base materials themselves.

Choosing the Right Oxy Gas Welding Kit

Factors to Consider When Purchasing

When shopping for an oxy gas welding kit, it’s crucial to consider various factors to ensure you select the right one for your specific needs:

- Type of Work: Determine whether you’ll be primarily welding, cutting, or heating, as some kits are specialized for certain tasks.

- Brand Reputation: Opt for reputable brands known for quality safety features and reliable performance. Brands like Victor, Harris, and Unimig are often recommended.

- Regulator Quality: A good regulator ensures consistent gas flow and reduces the risk of backfires; invest in a kit with high-quality regulators.

- Portability: If you need to move your kit regularly, consider the weight and size to ensure you can transport it comfortably.

- Replacement Parts Availability: Ensure the availability of spare parts and accessories, which can save time and effort in maintenance.

Top Brands and Models Available

Here are some notable brands and respected models in the market:

- Victor Equipment: Known for its reliable and robust systems, Victor’s kits are widely used in the industry.

- Harris: Offers affordable options equipped with high-quality regulators and hoses.

- Unimig: Their welding kits are designed for amateurs and professionals, balancing quality with affordability.

- Lincoln Electric: A well-known brand that provides excellent support and resources alongside a range of models suited for various welding needs.

Price Comparisons for Kits on the Market

Price comparison can assist users in selecting the kit that best fits their budget. The price range for oxy gas welding kits generally varies:

- Low-End Kits: Starting from $99, these often include basic components tailored for light-duty jobs.

- Mid-Range Kits: Ranging from $175 to $300, these provide a balanced mix of quality and performance suitable for both home and professional use.

- High-End Kits: Starting around $400+, these typically contain advanced technologies, superior safety features, and can handle demanding industrial tasks.

Safety Practices for Oxy Gas Welding

Essential Safety Gear and Equipment

Safety is paramount when handling an oxy gas welding kit. Essential safety gear includes:

- Welding Goggles or Helmets: Protects eyes from harmful UV rays and flying debris.

- Flame-Resistant Gloves: Safeguards hands from extreme heat and accidental burns.

- Long-Sleeve Clothing: Made of non-flammable materials to protect skin from sparks and heat.

- Safety Shoes: Steel-toed boots provide protection against heavy tools and equipment.

- Fire Extinguisher: Always have one nearby, ideally a Class B or C extinguisher, in case of any fire incidents.

Common Hazards and Prevention Strategies

As with any welding job, there are various hazards associated with oxy gas welding:

- Burns: Hot materials can cause serious injury; maintain a safe distance and always wear protective gear.

- Fume Inhalation: Exposure to harmful gases can occur; ensure adequate ventilation in your workspace.

- Explosions: Always handle cylinders carefully, following safety protocols for storage and use, and use proper regulators.

- Fire: Keep flammable materials away from the welding area; always work in a designated, safe environment.

Emergency Protocols and First Aid

In the event of an accident, it’s critical to be prepared with emergency protocols:

- Burns: For minor burns, cool the area with running water for at least 20 minutes; for more severe burns, seek medical attention immediately.

- Fume Exposure: If symptoms of fume inhalation occur (e.g., dizziness, headaches), move to fresh air and seek medical attention if symptoms persist.

- Eye Injuries: If eyes are exposed to intense light or debris, flush with water and seek help if vision is impaired.

Techniques for Effective Oxy Gas Welding

Basic Welding Techniques

Mastering fundamental welding techniques is essential for successful projects:

- Setting Up the Equipment: Ensure all hoses are leak-free and connections are secure before igniting the torch.

- Flame Adjustment: A neutral flame is usually ideal for welding; adjust the oxygen and acetylene levels to achieve a consistent, steady flame.

- Angle of the Torch: Maintain a proper angle (typically around 45 degrees) when welding to control the heat and workspace.

Troubleshooting Common Welding Issues

Even experienced welders face challenges; troubleshooting can help mitigate common problems:

- Excessive Spatter: May indicate too much heat or incorrect flame settings; adjust accordingly.

- Weak Welds: Can result from moving too quickly; ensure steady motion and an appropriate heat level.

- Inconsistent Flame: Check for blockages in the hoses or tips; clean or replace as necessary.

Advanced Techniques for Professionals

For those looking to refine their skills further, consider these advanced techniques:

- TIG Welding: Introduces an electric arc for higher precision and thinner metals, requiring mastery of complementary tools.

- Joining Multiple Seams: Techniques like weaving can strengthen the bond in wider seams, requiring skilled control of the flame.

- Metal Composition Awareness: Knowledge of the materials being welded (their melting points and properties) can lead to better control of heat and quality of weld.

Maintenance Tips for Your Oxy Gas Welding Kit

Regular Maintenance Routines

Keeping your oxy gas welding kit in good condition is essential for safety and performance:

- Inspect Regularly: Check hoses for wear and leaks, replace them as needed.

- Clean Tips: Regularly clean the torch tips and replace them if they show signs of excessive wear or distortion.

- Gas Cylinder Inspection: Always check that the cylinders are secured and properly stored to avoid accidents.

How to Store Your Kit Properly

Proper storage ensures safety and prolongs the life of your oxy gas welding kit:

- Cool, Dry Place: Store the kit in a dry area away from heat sources, reducing the risk of any gas combustion.

- Secure Cylinders: Always secure cylinders in an upright position, using chains or brackets, to prevent tip-over during storage.

- Protect Hoses: Roll hoses loosely and avoid sharp bends to prevent kinks that could impede gas flow.

When to Replace Components

Identify when components need replacement to maintain safety:

- Cracked or Leaking Hoses: Replace immediately—do not attempt to repair, as this can be hazardous.

- Worn-out Tips: If the tips have become distorted or are producing poor-quality flames, they should be replaced.

- Old Regulators: If regulators are not holding pressure properly or show physical damage, consider replacement without delay.